Typically, DLC coating provides a colorThis presented video contains the whole coating process by PVD method on stainless steel products PVD black color, PVD gold, PVD rose gold, PVD chroming coThe new PD2i coatings show that this not have to be the caseA boost in performance and appearance opens new markets or strengthen the current business New PVD Coatings we love colors!

What Is Pvd Coating Inori Co

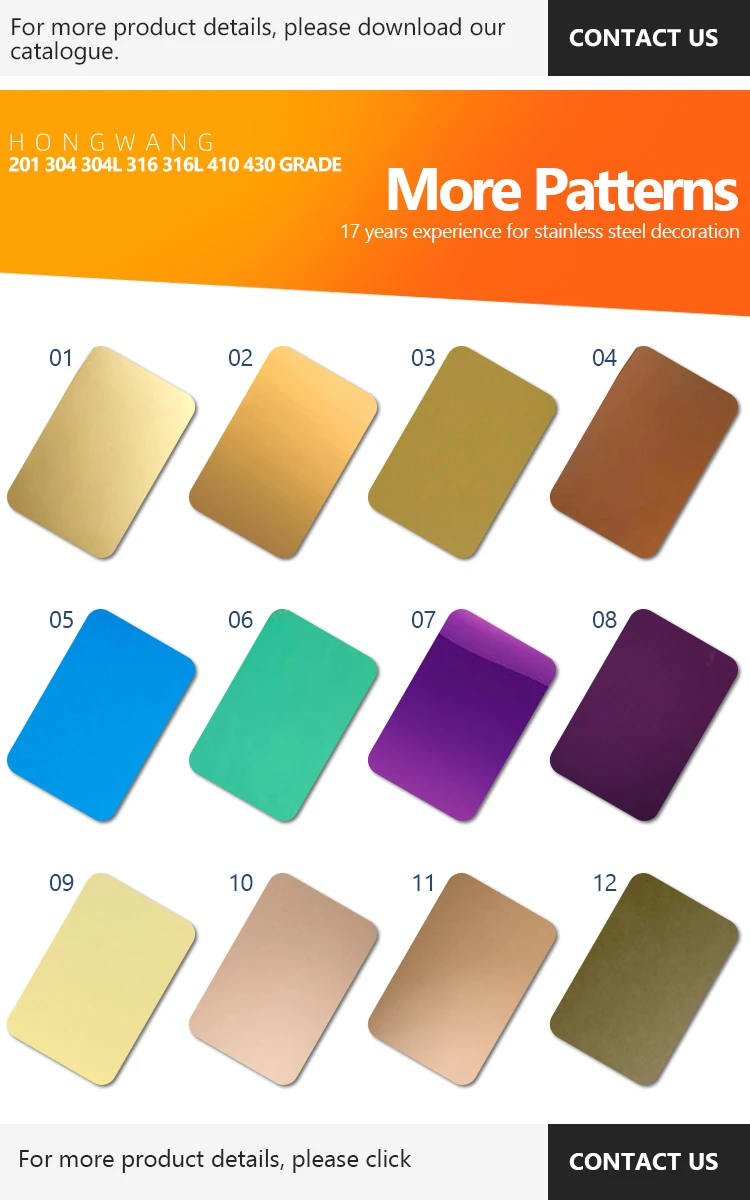

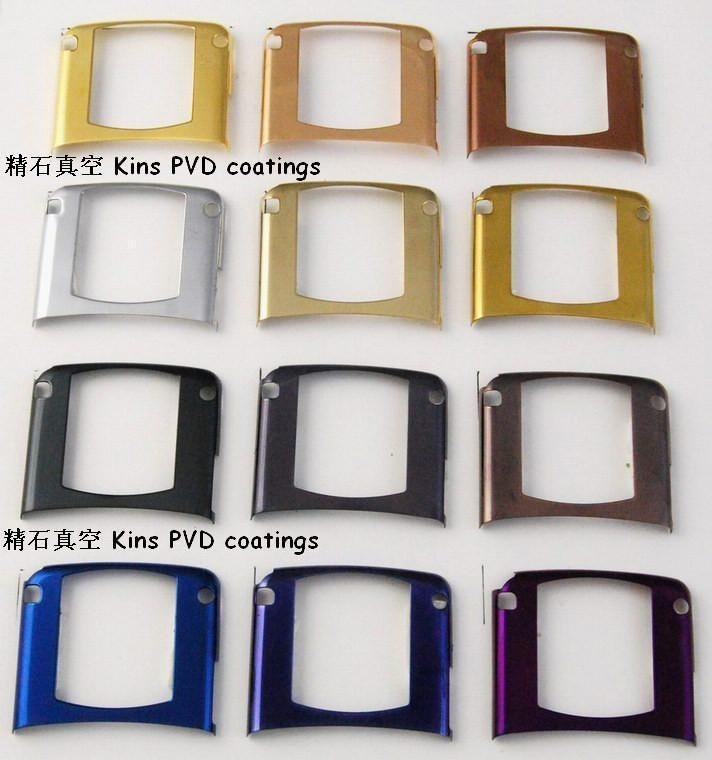

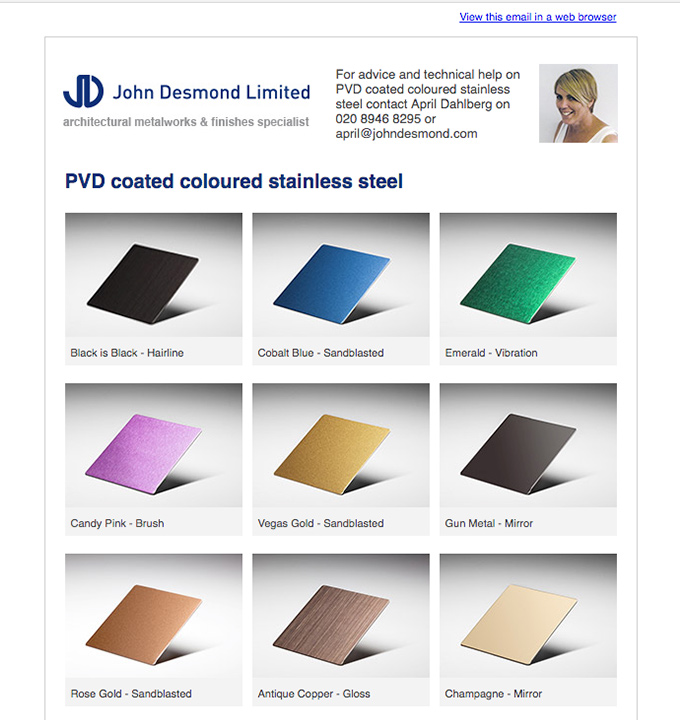

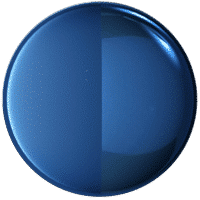

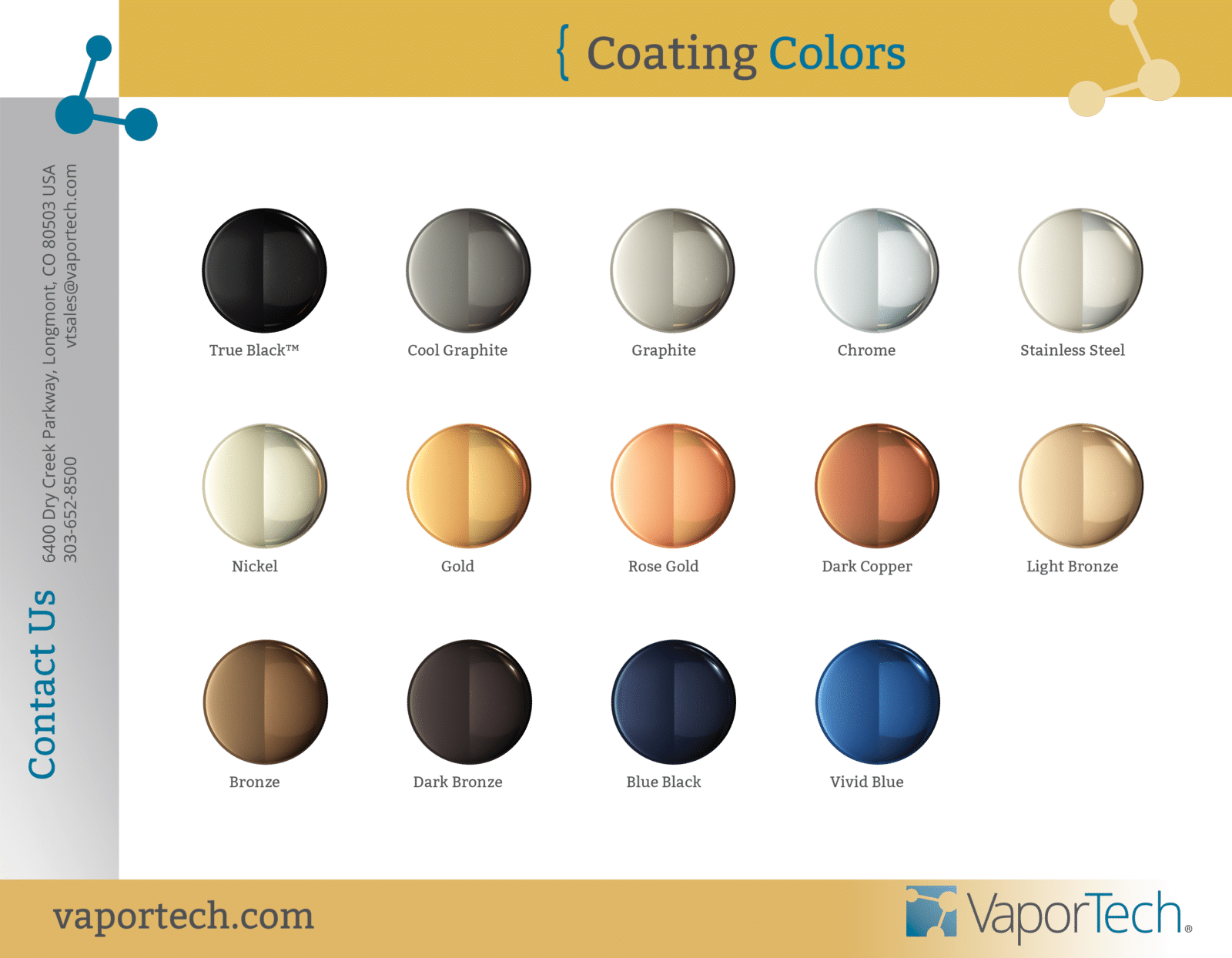

Pvd coating color

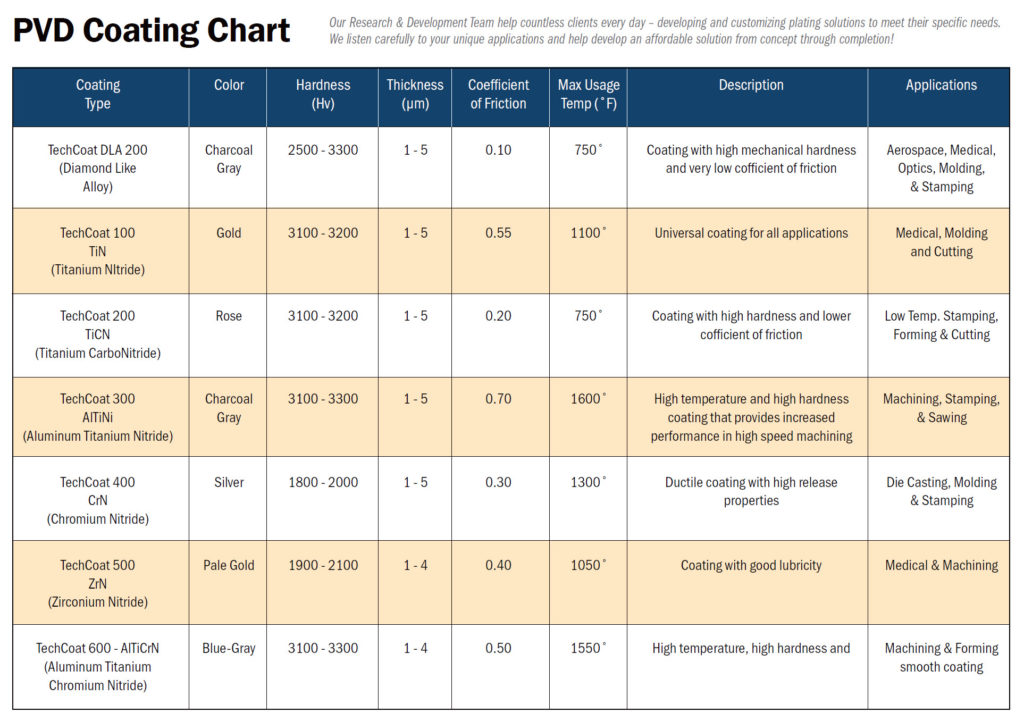

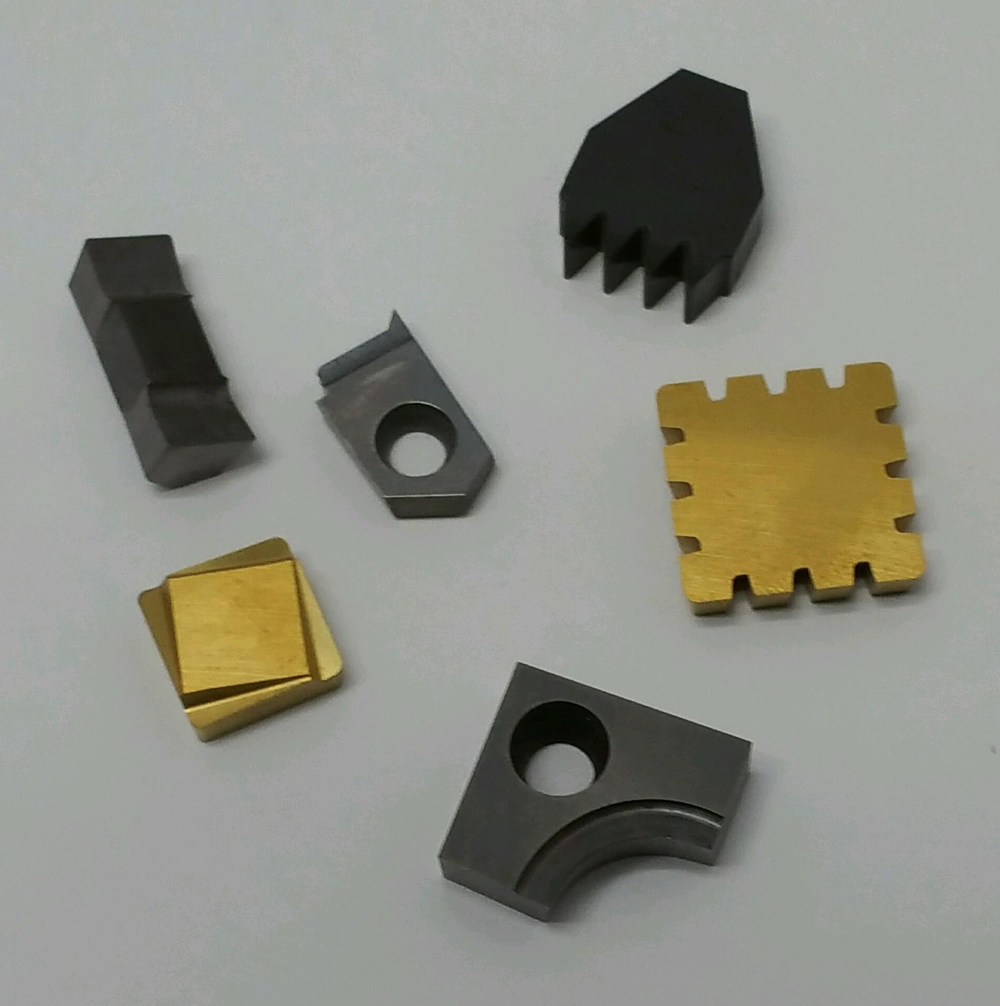

Pvd coating color-Check out titanium carbonitride (TiCN) PVD coating Adding carbon to a TiN film increases the hardness nearly 80 percent, resulting in additional tool life TiCN is an excellent allpurpose coating, but does particularly well in punching, injection molding and cutting tool applications TiCN is easily stripped from common tool steelsInfinium E is a Chromium Nitride based coating Infinium E is a tough, wear resistant coating with exceptional corrosion resistance It has higher oxidation resistance than Infinium T and Infinium C and, due to its chemical inertness, prevents adhesive wear Infinium E is silver in color and appears like polished stainless steel

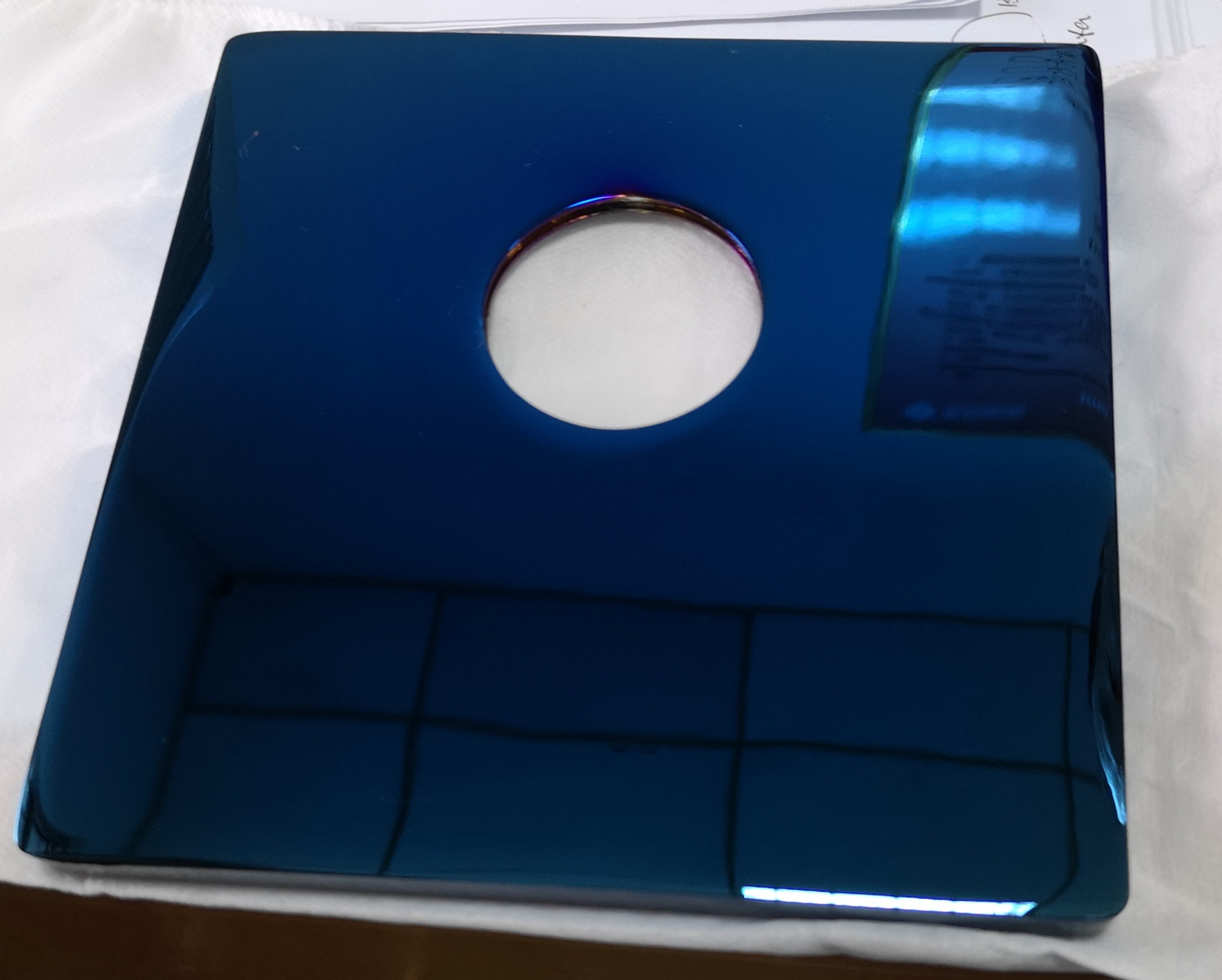

Durable All Round Coating In Interference Colours Blue 2 0 Eifeler High Tech Coatings

Gold plating vs Gold PVD We are often asked by customers to explain the difference between a gold color PVD coating and the more traditional gold plating methods PVD is a vacuum coating process that will produce a beautiful decorative and a very functional finish on Global No1 DSP Establish the standards for metal color coating technology We are manufacturing color inox, pvd coating colors, color metal Supplier in korea Touch screen panel Inverter cabinet Please share your expert opinion whether PVD coating machine with the above mentioned specifications is suitable for plasma coating of surgical instruments Colors required are gold, rose gold, blue, pink, green, hard

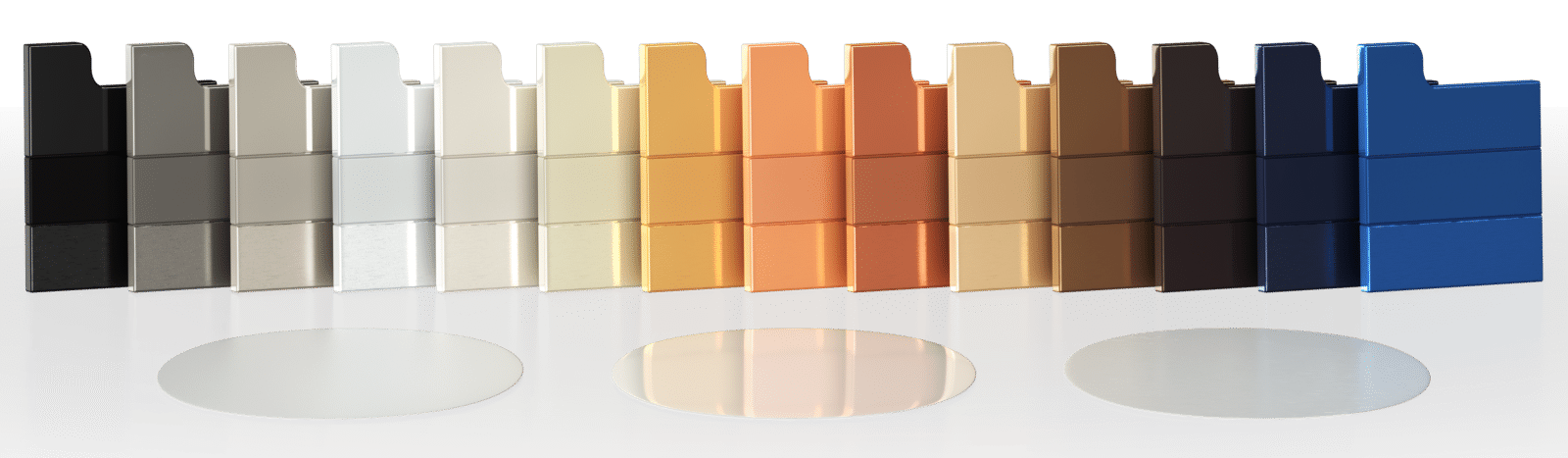

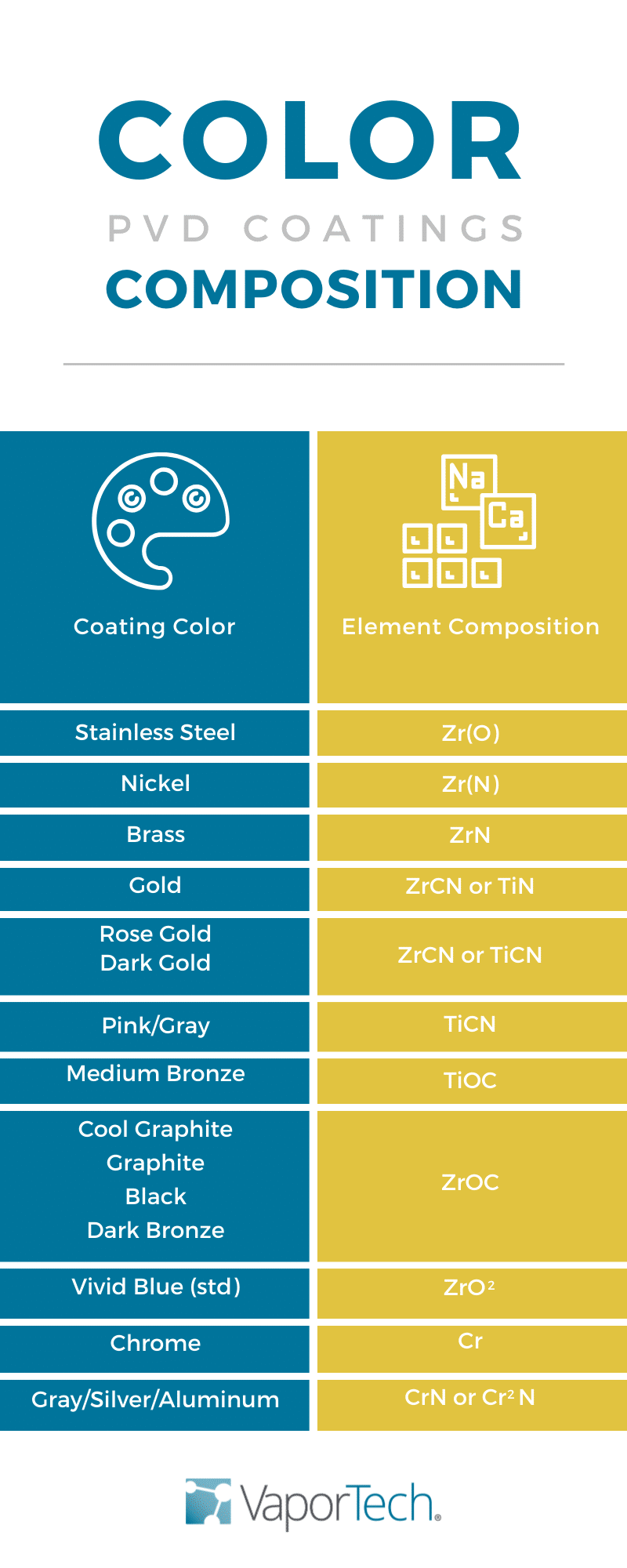

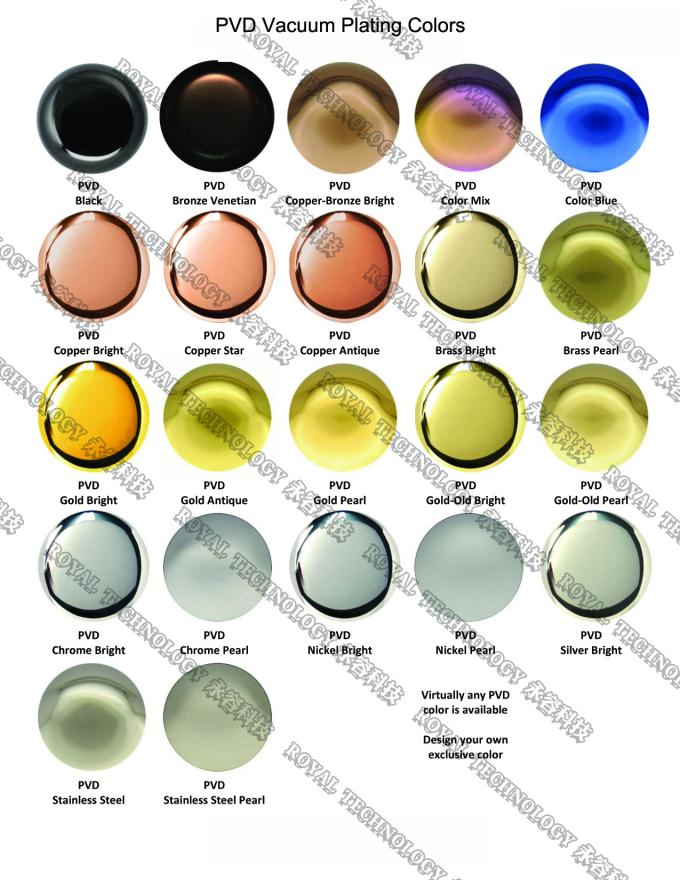

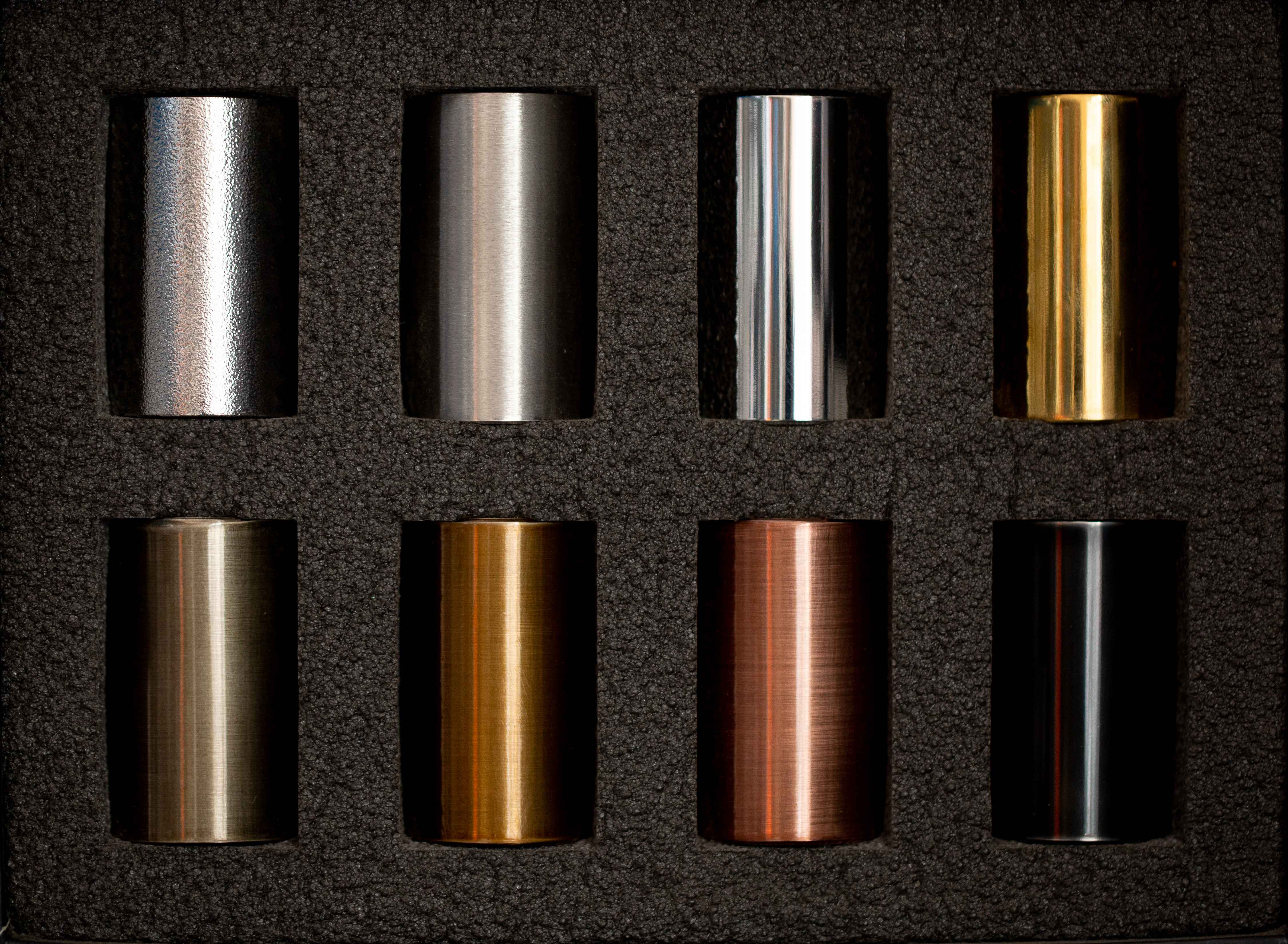

Unwavering Protection PVD Coating protects slides and barrels against normal wear and tear of your firearm After your gun is coated, you can expect an increased lifespan for your gun with unrivaled toughness and great lubricity that is so microthin that it doesn't interfere with operationDepending on the evaporated metal (target) and the mixture of reactive gases used during the PVD deposition process, different colors can be produced The range includes but not limited to Brass tones, Gold tones, Black to Grey, Nickel, Chrome, Copper and Bronze tones Does PVD coating scratch or fade?

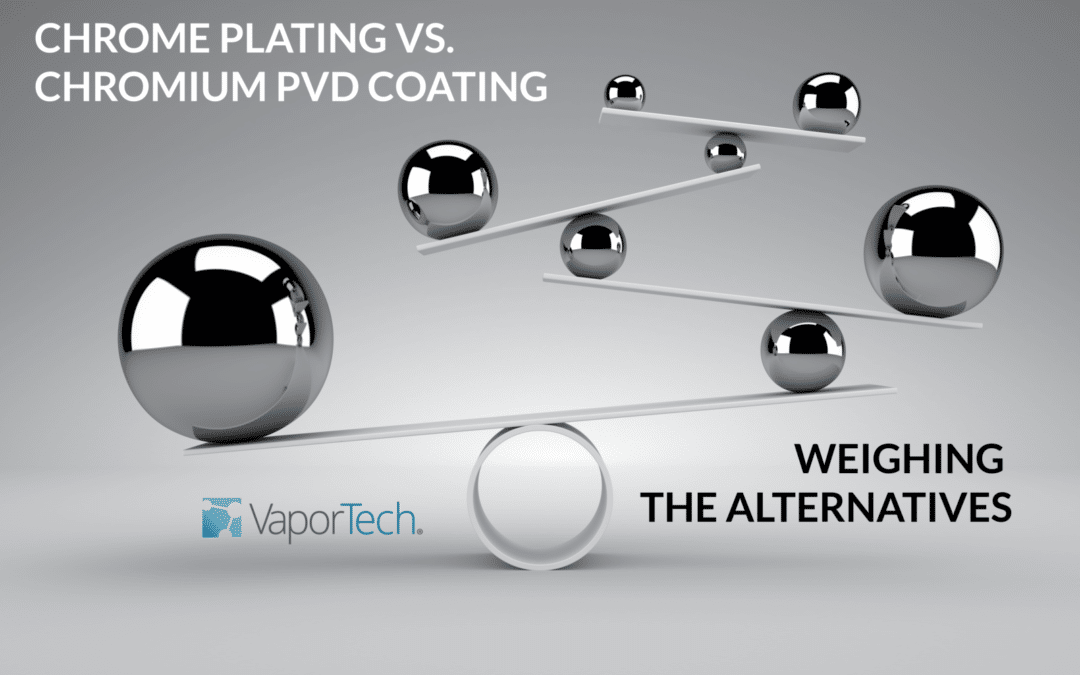

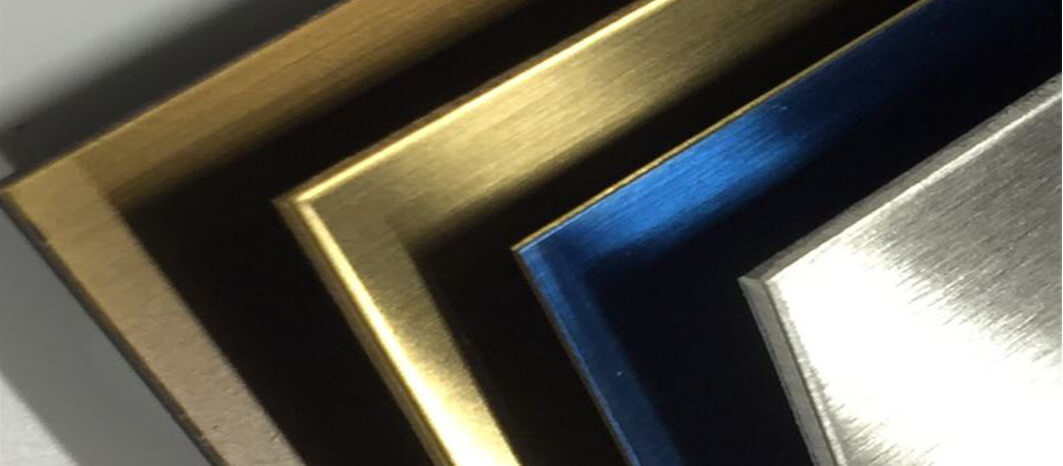

PVD coatings are considered a green process and are RoHS compliant PVD is a great choice for decorative finishes Can be applied in a smooth, brushed or bead blasted finish PVD has a significantly higher curability than chrome The LTAVD process can be used to apply PVD true black to plastics When performance and durability matter, considerArmor Guard is a family of PVD and CVD coatings that have been engineered for use within the firearms industry This range of processes and compositions allows us to match the best possible coating for each application, thereby ensuring the best performance based on Physical Vapor Deposition, or PVD, is a vacuum coating process that produces a brilliant decorative and functional finish PVD utilizes a titanium nitride that provides an extremely durable coating PVD coatings are more resistant to

Coloured Stainless Steel Pvd Coating

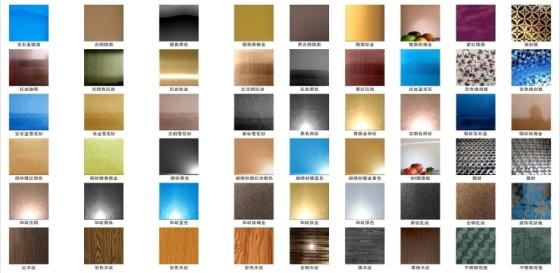

Pvd Coating Color Stainless Steel Sheet 1 304 316 430 Stainless Steel Texture Thickness 0 6 0 7mm Color Stainless Steel Buy Hongwang 1 304 Pvd Color Coil Stainless Steel For Metal Project Engineer Custom

The automotive industry uses PVD coating process for a variety of interior and exterior plastic trims Consumers always expecting a unique and tailored made color, Royal technology developed a new BROWN yellow color by ion plating as the request of car components manufacturer Royal team can assist you to develop more tailored coatings whichPerformance & industrial design pd2iWear, scratch and corrosion resistant PVD coloured stainless steel – Double Stone Steel in partnership with John Desmond Ltd Our PVD coating, developed by our partner Double Stone Steel, is an innovation in the creation of coloured stainless steel making the surface significantly harder and more durable in the process

Ear Tunnel Made Of 316l Steel Shiny Green Coloured Surface Pvd Coating Technology Jewelry Eshop

More Than A Pretty Color Absolute Black S Pvd Coating Mountain Bikes Press Releases Vital Mtb

The thickness of PVD coating The final coating choice is determined by the demands of the application The coating thickness ranges from 2 to 5 µm, but can be as thin as a few hundred nanometers or as thick as 15 or more µm The thickness of the watches Ops manufacture is usually with 6~8 µm Substrate materials include steels, nonferrousFast color change The treatment of PVD (Physical Vapor Deposition) coating improves the smoothness of the polymer on the metal, reducing the adherence effect and facilitating a fast color change This technology is characterized by a structure of 100 alternating layers of Chromium Nitride (CrN) and Niobium Nitride (NbN), whit a hardness of over 2500Hv and a coefficient ofColor Fastness – PVD films are colorfast over time Biocompatible – Richkote™ PVD coatings are chemically inert and hypoallergenic Versatility – Using our Richkote™ PVD coatings can allow a customer to transform a single uncoated substrate into a virtually limitless product line, simply by changing the appearance with our coatings

New Pvd Coatings We Love Colors Performance Industrial Design Pd2i

Pvd Coloured Stainless Steel Stainless Steel Steel Color

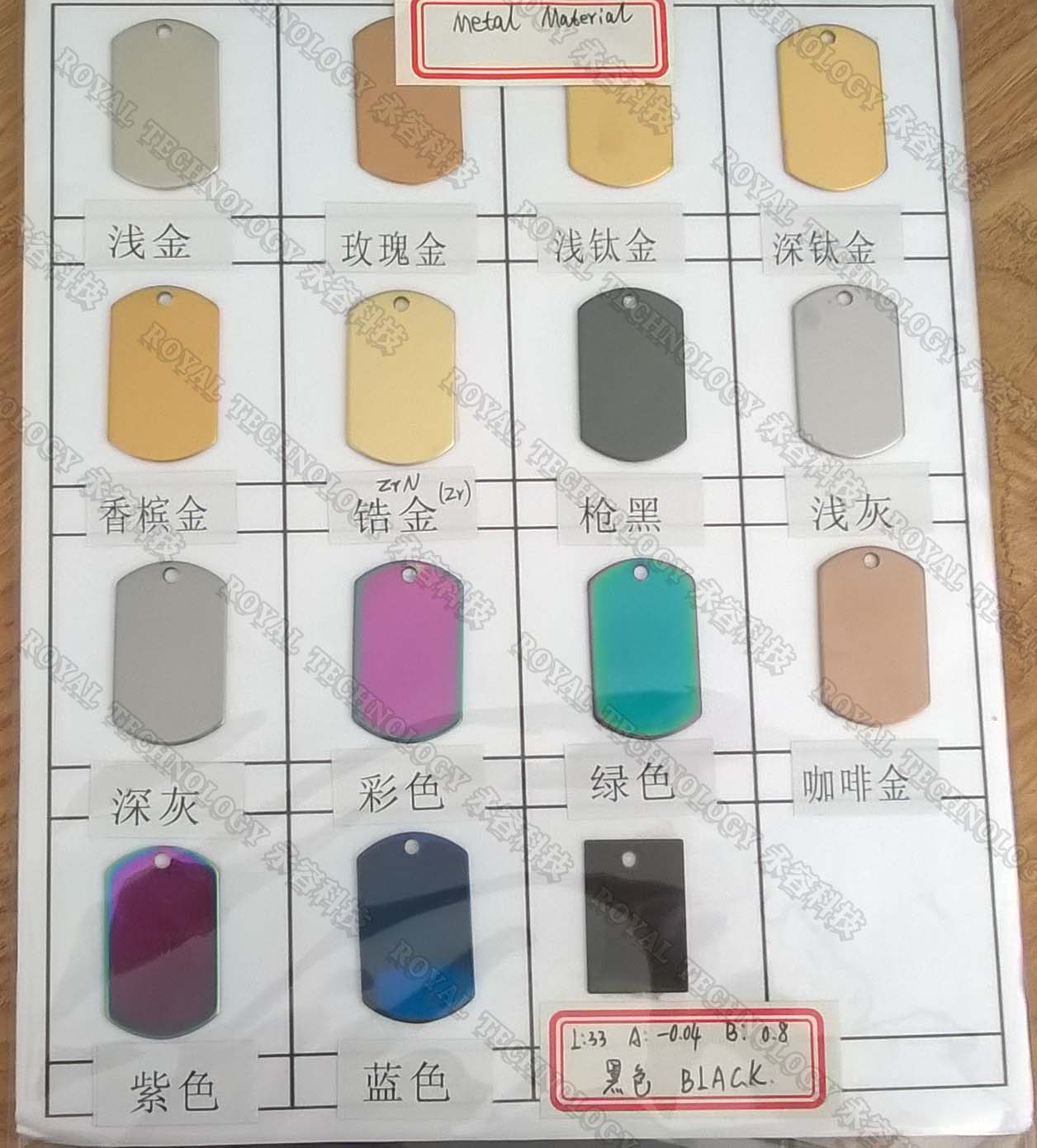

PVD Coating Color Formula IKSPVD has R&D center, for our equipment, we can supply the PVD coating color formula (not free, charge necessary fees)So if you have question, don't hesitate, contact with me now Email ikspvd@foxmailcom For example, Hard coatings are commonly used in decorative applications due to their Summary At present, PVD coating Evaporation vacuum coating machine can be produced in a variety of colors, such as dark gold, light gold, brown, bronze, grey, black, greyblack, sevencolor, purple, red, green, blue, etc, but most of them are gold, brown and black gray Different colors are plated by different target materialsPVD – Physical Vapor Deposition PVD is a highperformance coating with perfect sliding properties and very abrasion resistant surface In a highly complex thermoelectrolytical coating method it is applied at high pressure and about 450° Celsius Each cycle lasts about 46 hours

Why To Use Pvd Coating Foshan Jinxinsheng Vacuum Equipment

Tech Talk Pvd Coating Soul Performance Productssoul Performance Products

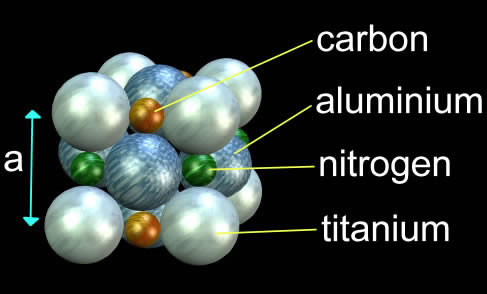

Description Calico Aluminum Titanium Nitride (AlTiN) is a hard coating that solves many tribological problems with components that can be coated at temperatures of 450°C 475°C CalicoAlTiN is normally applied to steels, hardened steels, and stainless steel materials where high wear resistance and lubricity are neededVacuum coating knowledge color Principle Principle of operation of the vacuum coating Physical Vapor Deposition (Physical Vapor Deposition, PVD) technology under the condition of vacuum, said by Physical method, the material source, the solid or the liquid surface gasification into gaseous atoms, molecules or partial ionization ion, and through the low pressure gas (or Another technical advantage of PVD is the ability to recreate the appearance of more costly metals such as copper, brass, bronze, and gold PVD coated metal will not patina You only need simple cleaning to keep the original copper color looking good Rose gold PVD can be found in jewelry, and black or gunmetal color is often used for watches

China 1 Color Pvd Coating Stainless Steel Sheet For Kitchen Decorative Photos Pictures Made In China Com

Gold Electroplating Vs Pvd Coating Calla Gold Jewelry

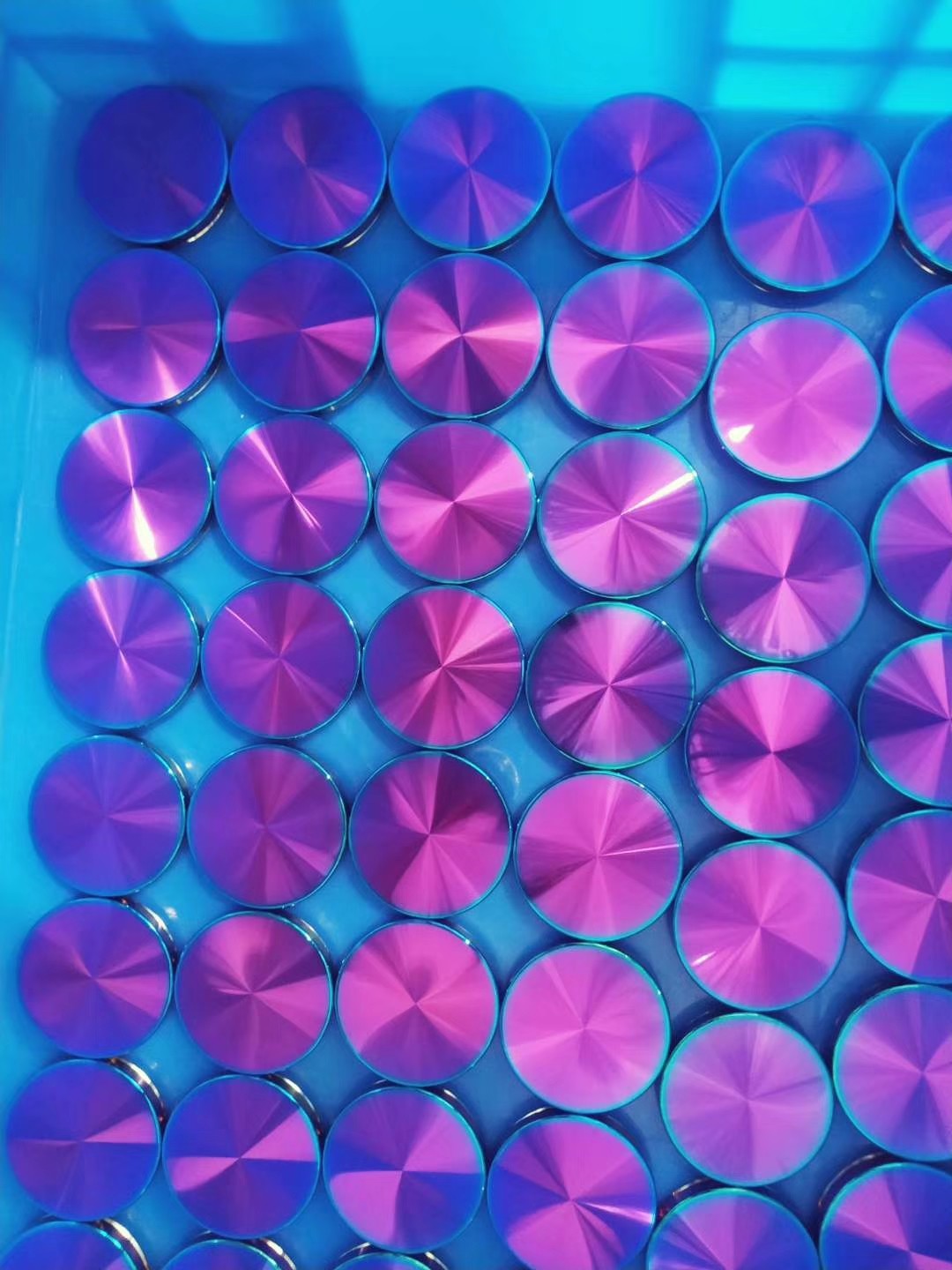

PVD Coatings Finishes and Codes Depending on the evaporated metal (target) and the mixture of reactive gases used during the PVD deposition process, different colors can be produced The range includes but not limited to Brass tones, Gold tones, BlackThe PVD hard material coating is carried out at eifeler almost exclusively by means of arc vapor deposition (electric arc vapor deposition ) with temperatures < 450 degrees centigrade With the arc process technology an excellent adhesion is achieved without hardness loss, distortion or change of the microstructure of the base materialRainbow Color PVD Coating Service / Metal PVD rainbow decoration color Royal Technology provides PVD coating services for rainbow color on various of substrate materials metals, steels, glass, ceramic, carbon steel, high speed steel, stainless steel, brass materials etc We have designed and produced rainbow color PVD coating machine more

Chrome Pvd Coating As An Alternative To Chrome Plating Vaportech

What Is Pvd Coating Advanced Coating Service

PVD Vacuum Deposited Coating Appearance Chromium metallic silver color Thickness Ranges from 025 to 15 microns Typical applications are 1 to 5 microns See the thickness conversion chart Uniformity Coating conforms uniformly to the substrate No buildup occurs on corners (unlike plating operations) Coating "throws" well into featuresThe PVD coating provides highly brilliant finishes with a wide range of colors including PVD Brass, PVD Gold, PVD TiGold, PVD Chrome, PVD Oil Rubbed Bronze, PVD Copper, PVD Diamond Black, PVD Black Pearl or PVD Black Rainbow These colors are derived from the following PVD coatings ; Extend the useful life of your cutting tools and reduce your manufacturing cost with PVD (Physical Vapor Deposition) coatings TiN, TiCN, TiAlN, ZrN, CrN, AlTiN coatings and more Many coating jobs can be done in 24 hours

Black Color Pvd Coating Service For Stainless Steel Glass And Ceramic Items

Pvd Coating Physical Vapor Deposition Dlc Coating Ams 2444

A PVD gold or platinum coating produces brilliant finishes that make watches highly resistant to scratches and scrapes that cause less resilient processes to wear off Titanium nitride and similar coatings offer beautiful finishes that are also very resistant to corrosion and wearOur PVD coating is an innovation in the creation of coloured stainless steel making its surface ten times harder and more durable in the process This is created through the process of PVD (Physical Vapor Deposition) Titanium Ion Plating which improves the performance of stainless steel by increasing wear, scratch and corrosion resistanceCaring for your coloured cutlery The cutlery you acquired is made of 18% (18/0) quality stainless steel and safe for contact with food This coloredPVD (Physical Vapor Deposition) cutlery features a thin titanium coating that offers a vibrant color This cutlery is dishwasher proof when taking into account our instructions

Durable All Round Coating In Interference Colours Blue 2 0 Eifeler High Tech Coatings

Stainless Steel Pvd Coated Colour Profile For Construction Rs 75 Foot Id

Zirconium Nitride (ZrN), Zirconium Carbon Nitride (ZrCN PVD coating method with adjustable color of target film 1 The product to be plated is introduced into the coating chamber with metal target, and the pumping vacuum and heating device are started to heat the substrate, so that the background vacuum reaches 1 × 103pa After reaching the process temperature of ℃, sccm argon gas is injected into thePhysical vapor deposition (PVD) is an ecofriendly vacuum method metalizing coating which has benefits related to colors, texture, precision and functionalities over traditional decorative coating methods as brush, dipping, spay, electrophoretic PVD coating works notoriously well on bathroom finishes, kitchen cutlery, and plastic automotive parts

Leader Pvd Coatings In Conto Terzi Pvd Technologies

Pvd Pink Colors Coating On Glass Metal Steel Parts

7 Different kinds of Colors of PVD Coatings At present, the colors of the PVD coatings are mainly as follows deep gold color, light gold color, brown, bronzecolored, grey, black, greyblack, iridescence etc Through controlling of the parameters of coating process, we can control the colors of the PVD coatingsAn unequaled finish in pvd coatings Put simply, West Coast PVD fuses color onto metal to create an unequaled finish like you've never seen before PVD coating technology uses an environmentally friendly process to create a beautiful and durable thin film metal coating, creating vibrant colors that can last a lifetimePVD/DLC Coatings for firearms, gun parts, supressors, blades TiN, TiAlCN, AlTiN Apply a coating to protect your firearm or knife and give it a unique look Call 1 (909) Add a golden design to create an exclusive look Learn more about TiN Sucaslide® Learn more about Sucaslide®

Pvd Physical Vapour Deposition Colour Options For The Apple Watch Physical Vapor Deposition Color Options Color

The Three Different Types Of Pvd Coating Bend Plating

– PVD Coating durability You may like the sporty and robust look of a PVD coated watch, but may be afraid that it will wear off over time The issue is that the PVD coating is black, and applied onto the steel As such, if the PVD coating would come off, the bright white steel would stand out very clearly PVD Coating can change the color of stainless steel to look like materials such as brass and bronze Its decorative attribute is also seen in smartphone finishes For example, Apple uses it in making the Space Gray and Gold finishes used in the iPhone series PVD Colors PVD coatings can be produced in a wide color range Several target materials can be chosen as long as they are conductive for arc evaporation technology Metals used as target material in decorative PVD processes are zirconium, titanium, chromium, titaniumaluminum alloys and niobium

Durable Pvd Finishes Color Coatings The Future Is Bright Vaportech

Wear Resistant Corrosion Resistant Pvd Decorative Color Coating Kins China Manufacturer Others Designing Processing Custom Made

Depending on the ratio of aluminum to titanium in the coating, AlTiN coating provides higher surface hardness than TiAlN coating, making it another viable coating option for highspeed machining IKS PVD company, decorative coating machine, tools coating machine, optical coating machine, PVD vacuum coating line, the turnkey project is available With DLC coatings, significant improvements in hardness can achieve up to 9000 Vickers, which is much higher than PVD's hardness levels or by any other surface coating method Pvd vs DLC, which is best?Dobek says that a good way to understand PVD coating is to think about a common household item the drill bit The gold or black color on the surface of the bit is PVD Not only does this provide wear resistance to the bit, it makes it much more aesthetically appealing

Durable Pvd Finishes Color Coatings The Future Is Bright Vaportech

Sale Pvd Plated Stainless Steel Is Stock

Titatium Coating Technology The New World Of Eco Friendly Stainless Steel Product Manufacturer Dsp

Rainbow

Pvd Coating Physical Vapor Deposition Dlc Coating Ams 2444

What Is Pvd Coating Advanced Coating Service

Custom Finishes Instinct Hardware

Richkote Decorative Pvd Coating Technology Physical Vapor Deposition Richter Precision

Pvd Color Coated Stainless Steel Sheets Color Sheets Id Buy China Decoration Stainless Steel Sheet Color Stainless Steel Sheet Pvd Coated Color Sheets Ec21

Glass Jars Rose Gold Pvd Coating 0 5 3 Microns Thin Film Coating Services

Introduction To Pvd Coatings Sam Sputter Targets

Interior

Baltone Decorative Colours

Customized Pvd Coating Coloured Stainless Steel Sheet Manufacturers Suppliers Factory Direct Price Anhuilong

More Than A Pretty Color Absolute Black S Pvd Coating Mountain Bikes Press Releases Vital Mtb

Engineered Pvd Coating Techcoat 600 Alticrn Metal Finish

Pvd Coating Color Finishes Provide Feel Of Customization

Abs Plastic Parts Pvd Arc Plating Gold Color Plastic Gold Coating Service By Ion Plating

Blue Color Pvd Coating On Metal Parts Brass Alloy Pvd Blue Coating Service

Atop Rainbow Color Pvd Vacuum Coating Machine Buy Rainbow Color Pvd Coating Machine Rainbow Color Vacuum Coating Machine Rainbow Color Pvd Vacuum Coating Machine Product On Alibaba Com

Pvd Coating Mim Parts Metal Injection Molding

Tio Rainbow Color Pvd Coating Equipment Tin Gold Plating On Glassware Multi Arc Pvd Plating Machine

Rainbow Pvd Plating Decorative Colors Coating Service Shisha Glassware Vacuum Coatings

Stainless Steel Pvd Coated Color Profile For Construction Rs 110 Feet Id

Pvd Coating Coloured Stainless Steel Sheet Price Supplier Manufacturer Shanghai Metal Corporation

Aluminum Titanium Nitride Altin Pvd Coating Calico Coatings

Download Education Guide Vaportech

Decorative Pvd Coatings Impact Coatings

Jewelry Gold Pvd Coating Machine

Colored Pvd Coating Finish Sheet Plates Stockist Supplier In Mumbai India

Richkote Decorative Pvd Coating Technology Physical Vapor Deposition Richter Precision

What Is Pvd Physical Vapor Deposition Design Strategies

Rainbow Titanium Nitride

Precise Coating Thickness Measurement On Pvd Coated Tools Xrf Analysis

China Building Material Pvd Color Coating Stainless Steel Sheet China Pvd Coating Stainless Steel Sheet Stainless Steel

51 Our Work Coloured Stainless Steel Ideas Steel Stainless Steel Stainless

Coatings Pvd Coatings Vs Liquid Metal Coating

Multi Color Pvd Coating Stainless Steel Sheets And Plates Surface Finishing Hairline For Home Design Buy Hairline Finish On Stainless Steel Pvd Coating Surface Finishing Product On Alibaba Com

Communications John Desmond Ltd

The Latest Trend In Pvd Develop New Pvd Colors

Glass Bottle Rainbow Color Pvd Coating Machine Equipment China Bottle Coating Equioment Bottle Coating Machine Made In China Com

Pvd Coating

Pvd Color Coated Stainless Steel Sheets Steel Grade Ss304 L Rs Piece Id

Pvd Coating Finishing And Colours Available Pvd Technologies

Bowl Gold Coloured Medium 10cm Pvd Coated Playground

Golf Club Pvd Plating Equipment Black Color Pvd Coating Machine For Golf Club View Golf Club Pvd Coating Equipment Huicheng Product Details From Guangdong Huicheng Vacuum Technology Co Ltd On Alibaba Com

Pvd Physical Vapor Deposition Coating Multi Layered And Composite Heat Resistant Coatings At Ti Coating Ti Coating Inc

Colour Options For Pvd Physical Vapor Deposition Vapor Physics

Pvd Colored Stainless Steel Double Stone Steel

How Is Coloured Stainless Steel Made Pvd What Are Its Uses

What Is Pvd Coating Inori Co

Pvd Coating Color Gold Stainless Steel Sheet Decorative Exterior Wall Cladding

How To Add Color To Jewelry Quick Jewelry Repairs

Colored Pvd Coating 6000mm Stainless Steel Pipes Tubes Manufacturer Factory Price

What Are Pvd Coatings Pvd Coatings

Amazon Com Stainless Steel Motorcycle Chain Bracelet With Solid Black Pvd Coating Link Bracelets Clothing Shoes Jewelry

1

Stainless Steel Color Coated Profiles Sections Columns In 304 Pvd Ti Coated Sds Profile

Colored Pvd Coating Finish Sheet Plates Stockist Supplier In Mumbai India

Pvd Coated Decorative Film Pvd Coating Color

New Pvd Coatings We Love Colors Performance Industrial Design Pd2i

China Stainless Steel Kitchenware And Tableware Gold Color Pvd Coating Machine China Stainless Steel Kitchenware Pvd Coating Machine Kitchenware Gold Coating Machine

Gold Brass Black Rose Gold Chrome Blue Silver Pvd

Pvd Coating Smn Industries

Pvd Coatings Metal Polishing Electroploating And More Bend Plating

Education Pvd Coating Vapor Tech

Pvd Coating Spectrum Pvd Coating

Pvd Coatings Voestalpine Hpm International

Dsp Beyond Your Imagination

Pvd Coating Stainless Steel Sheets From Stanch Trustworthy Pvd Coated Stainless Steel Plate Suppliers

Richkote Decorative Pvd Coating Technology Physical Vapor Deposition Richter Precision

Pvd Benefits Learn About The Benefits Of Decorative Pvd Coatings

Inubia B6 B12 Oerlikon Balzers

What Is Pvd Coating Finish Physical Vapor Deposition

Pvd Coating Finishing And Colours Available Pvd Technologies

Types Of Pvd Coating Pvd Coating Colors Vaportech

Pvd Coating Services Sas Tactical Customs

Coloured Stainless Steel Pvd Coating

Pvd Coated Stainless Steel Sheet Exporters Ss Pvd Coated Sheet Suppliers

Stainless Steel Flatware Pvd Coating Service Cathodic Arc Plating Rose Gold Copper Colors For Sale Pvd Coating Service Manufacturer From China

Pvd Color Coated Stainless Steel Sheets Color Sheets Id Buy China Pvd Coated Color Sheet Stainless Steel Sheet Stainless Steel Color Sheet Ec21

What Is Pvd Coating

0 件のコメント:

コメントを投稿